Membrane switches may look simple from the outside, but inside, they are engineered with precision. Whether used in medical devices, industrial control panels, or consumer electronics, their reliability depends heavily on their internal structure.

In this post, we’ll walk through the construction of a membrane switch, layer by layer, explaining how each component contributes to its performance, durability, and functionality.

What Is a Membrane Switch?

A membrane switch is a thin, flexible electrical switch that activates a circuit when pressure is applied to the surface. It’s widely used in electronic interfaces where space is limited and rugged performance is essential.

But what makes them work so well? The secret lies in their multi-layered construction.

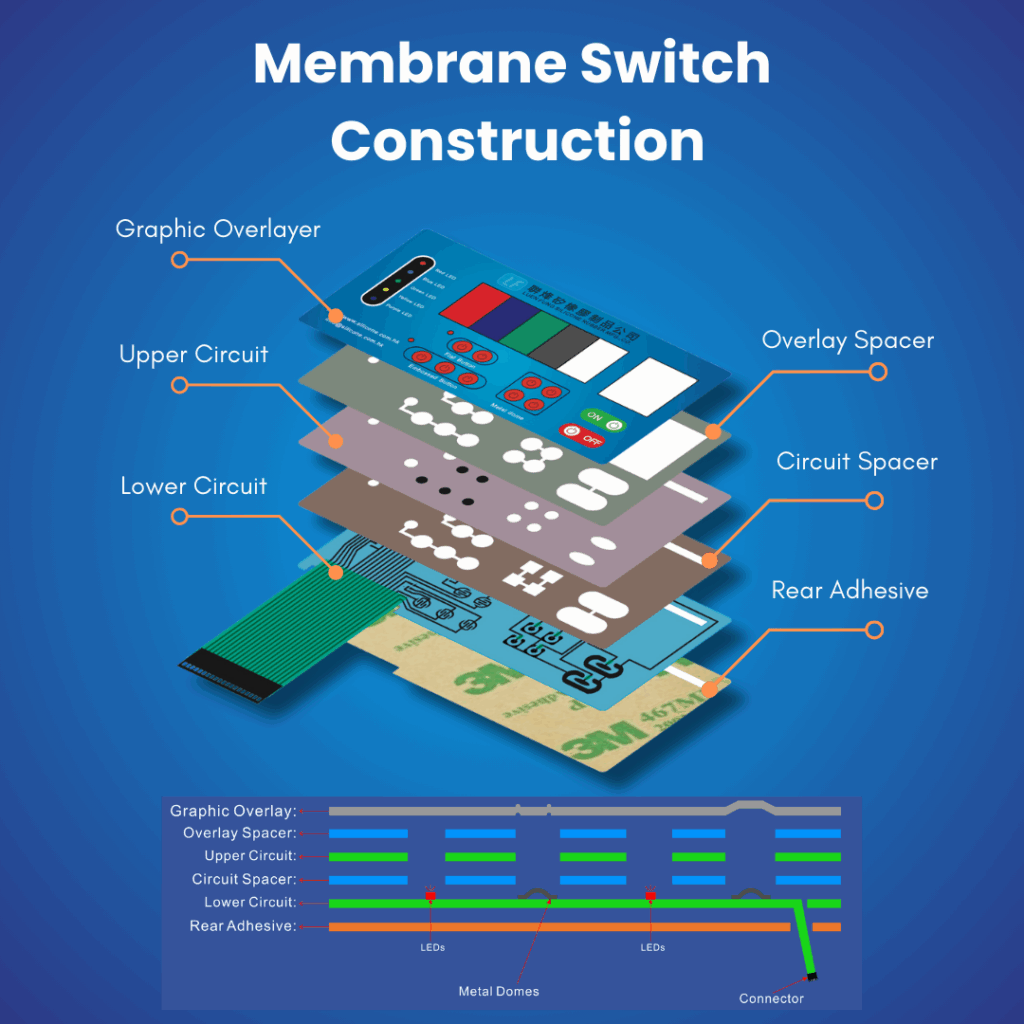

Membrane Switch Structure: A Layer-by-Layer Breakdown

1. Superposición Gráfica

The topmost layer that the user interacts with.

- Material: Usually made from polyester (PET) or polycarbonate (PC)

- Function: Displays printed icons, text, and logos; protects the inner layers

- Custom Features: Embossing, transparent windows, backlighting zones, anti-scratch or matte finishes

🟢 User tip: The graphic overlay is fully customizable to match brand identity and enhance user experience.

2. Overlay Adhesive

A thin layer of pressure-sensitive adhesive (PSA) that bonds the graphic overlay to the upper circuit or spacer.

- Function: Maintains alignment, keeps dust and moisture out

- Material: Acrylic or polyester-based adhesive

🟡 This layer must be optically clear around display windows or LED zones.

3. Dome Retainer Layer (only in tactile switches)

Holds metal or polyester domes in place.

- Function: Ensures domes stay aligned for tactile feedback

- Customizable: Dome shape, size, and actuation force

🟠 Note: This layer may be omitted in non-tactile membrane switches.

4. Spacer Layer

Separates the top and bottom circuit layers to prevent unintended contact.

- Function: Creates a dead zone around each key to prevent accidental actuation

- Features: Cut-outs at switch locations allow contact when pressure is applied

🔵 Design tip: Proper alignment and material thickness are critical to ensure switch performance.

5. Top Circuit Layer

Printed with conductive traces using silver, carbon, or copper.

- Material: PET with screen-printed conductive ink

- Function: Carries the top half of the circuit

- Variants: May include integrated LEDs or resistors

6. Spacer or Circuit Adhesive

This layer holds the top and bottom circuits together while insulating them.

- Material: Thin PSA with cut-outs at key locations

- Function: Allows circuit contact only at defined actuation points

7. Bottom Circuit Layer

Printed with the lower half of the circuit pattern.

- Material: PET or flexible copper

- Function: Completes the circuit when pressed

- Customization: Shielding or ground planes can be added here

8. Rear Adhesive

Used to mount the membrane switch onto the product enclosure or panel.

- Material: High-strength PSA

- Function: Provides long-term adhesion to various surfaces

- Optional: Can include venting channels or foam for sealing

➕ Optional Layers & Add-ons

Depending on the application, membrane switches may also include:

- EMI/RFI Shielding Layer – Protects against electromagnetic interference

- Backlighting Layer – EL, LED, or fiber optic for visibility in low-light conditions

- ESD Protection Layer – Prevents electrostatic damage

- PCB or Rigid Backer – For hybrid switch assemblies

Real-World Applications

Medical Equipment – Sealed design, easy to clean

Controles industriales – Rugged for harsh environments

Electrónica de consumo – Sleek look, low profile

Military/Aerospace – EMI shielding, extreme durability

Conclusion

he construction of a membrane switch is much more than meets the eye. Every layer — from the graphic overlay to the adhesive backing — plays a key role in how the switch performs, feels, and lasts.

At Luen Fung, we specialize in designing custom membrane switches tailored to your application, with optional features like LED integration, metal domes, and EMI shielding.

👉 Contact us info@silicone.com.hk to request a prototype or get a quote for your next project.