When designing a membrane keypad, one of the most important — yet often overlooked — components is the graphic overlay. It’s the topmost layer that users see and touch, and it plays a crucial role in both appearance and performance.

Choosing the right overlay material affects not only the look and feel of your interface but also its durability, resistance to environmental conditions, and overall user experience.

In this guide, we’ll walk you through the most common materials used for graphic overlays and how to choose the best one for your application.

What Is a Graphic Overlay?

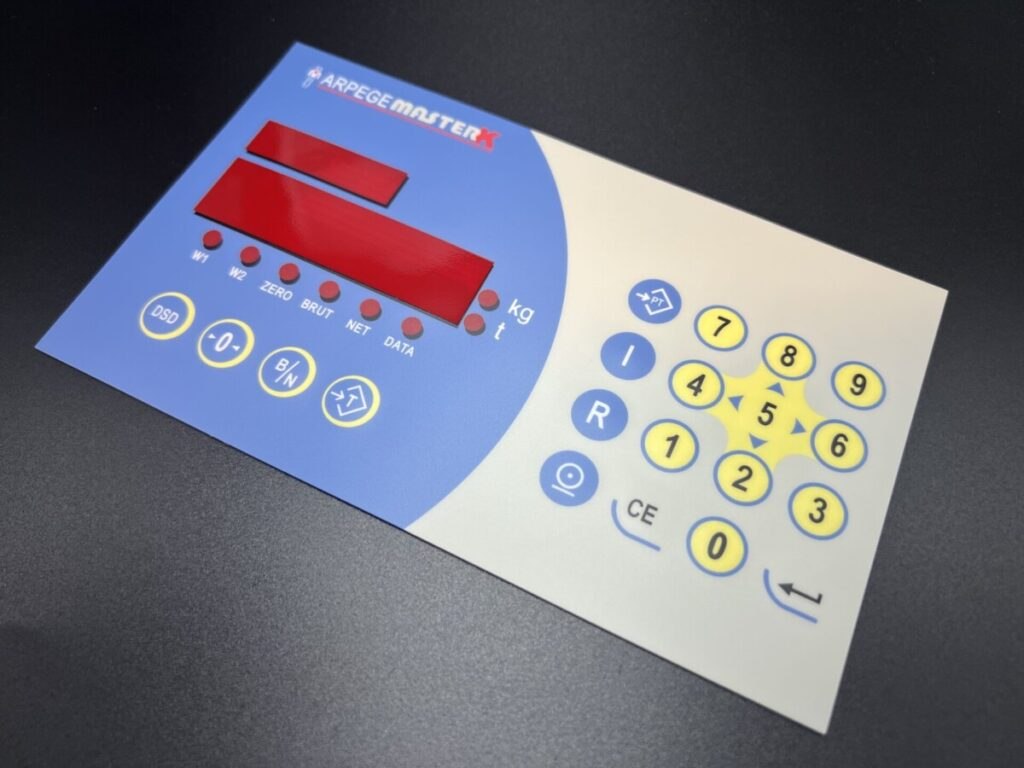

A graphic overlay is the printed surface layer of a membrane switch or keypad. It provides:

- Visual cues (symbols, icons, text)

- Tactile feel through embossing or coatings

- Environmental protection for the internal circuitry

- Brand identity with custom designs and logos

Common Materials for Graphic Overlays

There are two main materials used in most membrane keypads:

1. Polyester (PET)

Most Popular for Industrial Applications

- High durability and chemical resistance

- Excellent flex life — won’t crack over time

- Compatible with embossing and tactile feedback

- Maintains clarity even with repeated cleaning

- Often used in: medical devices, industrial equipment, military-grade interfaces

Best choice if your device will be used frequently or exposed to cleaning agents, solvents, or mechanical wear.

2. Polycarbonate (PC)

Used in Low to Medium-Duty Applications

- Easy to print on and die-cut

- Good optical clarity and design versatility

- Smooth surface options for user-friendly feel

- Less resistant to chemicals and abrasion than polyester

- Often used in: consumer electronics, office equipment, point-of-sale terminals

Suitable for lower-impact applications or where design flexibility and cost are more important than extreme durability.

Key Factors to Consider When Choosing Overlay Material

1. Environmental Exposure

- Use polyester for exposure to chemicals, UV light, and outdoor environments

- Use polycarbonate for indoor or clean environments

2. Expected Lifespan

- Polyester lasts millions of actuations without fatigue

- Polycarbonate is better for shorter lifecycle products

3. Tactile Requirements

- Both materials support embossing (pillow or rim)

- Polyester holds embossing shape longer, especially in high-use products

4. Aesthetic Preferences

- Polycarbonate offers better clarity and options for textured or glossy finishes

- Both support transparent windows for displays and backlighting

5. Printing Method

- Screen printing and digital printing work well on both materials

- For backlit or multi-color designs, polycarbonate may be more cost-efficient

Optional Enhancements for Overlays

No matter which base material you choose, overlays can be customized with:

Adhesive backing – for bonding to the rest of the membrane switch assemblyironments.🔵 Design tip: Proper alignment and material thickness are critical to ensure switch performance.

Hard coat coatings – for scratch resistance

Anti-glare / anti-fingerprint finishes

UV-resistant inks – to prevent fading in sunlight

Laser etching – for light-transmitting icons or backlit legends

Embossing – for tactile buttons or decorative elements

Quick Comparison Table

| Feature | Polyester (PET) | Polycarbonate (PC) |

|---|

| Durabilidade | ★★★★★ (High) | ★★☆☆☆ (Moderate) |

| Chemical Resistance | Excellent | Fair |

| Print Clarity | Good | Excellent |

| Embossing Retention | Excellent | Moderate |

| Cost | Moderate | Lower |

| Common Use Cases | Industrial, Medical | Consumer, Office Equipment |

Real-World Applications

Here are just a few examples of how membrane switches extend equipment durability:

| Industry | Use Case | Benefit |

|---|---|---|

| Medical | Patient monitors, autoclave controls | Easy to sterilize, resists disinfectants |

| Industrial | Machine control panels, PLC HMIs | Dust-proof, vibration-resistant |

| Agriculture | Outdoor irrigation systems | UV, water, and mud resistant |

| Food Processing | Touch controls on washdown-rated equipment | Chemical- and water-resistant |

| Transportation | Dashboards, keypads for rugged handhelds | Shockproof, reliable in cold/hot temps |

Conclusion

The graphic overlay is more than just a label — it’s a key component of your membrane keypad’s durability, functionality, and user experience. Choosing the right material ensures your product will perform as expected, look professional, and stand up to its working environment.

✅ For rugged, long-lasting applications: choose polyester (PET)

✅ For cost-sensitive or visually rich designs: choose polycarbonate (PC)

👉 Need help selecting the right overlay for your membrane switch?

At Luen Fung, we offer full customization with material, embossing, backlighting, and adhesive options to meet your needs.

📩 Contact us today for expert advice or a free quote.